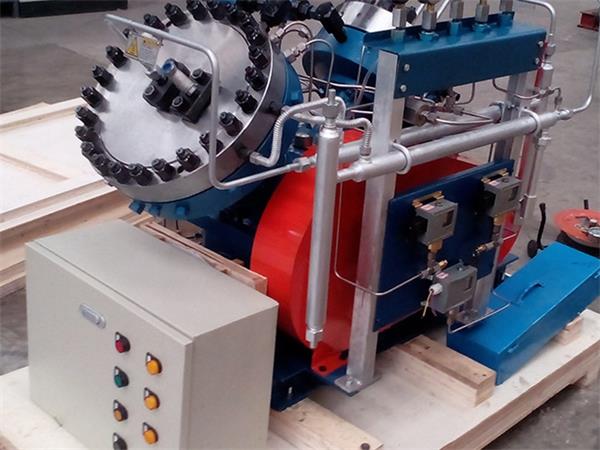

I-Diphragm compressor iwuhlobo olukhethekile lwe-compressor oludlala indima ebalulekile emikhakheni eminingi ngesakhiwo sayo esiyingqayizivele kanye nesimiso sokusebenza.

1. Ukwakheka kwesakhiwo se-diaphragm compressor

I-compressor ye-diaphragm ikakhulukazi iqukethe izingxenye ezilandelayo:

1.1 Indlela yokushayela

Ngokuvamile inikwa amandla yinjini kagesi noma injini evuthayo yangaphakathi, amandla adluliselwa ku-crankshaft ye-compressor ngokusebenzisa ukudluliselwa kwebhande, ukudluliswa kwegiya, noma uxhumano oluqondile. Umsebenzi womshini wokushayela uwukunikeza umthombo wamandla ozinzile we-compressor, ukuqinisekisa ukuthi i-compressor ingakwazi ukusebenza ngokujwayelekile.

Isibonelo, kwamanye ama-compressor amancane we-diaphragm, injini yesigaba esisodwa ingase isetshenziswe njengendlela yokushayela, kuyilapho kuma-compressor amakhulu e-diaphragm yezimboni, ama-motor aphakeme wesigaba sesithathu noma izinjini ezivuthayo zangaphakathi zingasetshenziswa.

1.2 Umshini wokuxhuma we-Crankshaft

I-crankshaft yokuxhuma i-rod mechanism ingenye yezingxenye eziyinhloko ze-compressor ye-diaphragm. Iqukethe i-crankshaft, induku yokuxhuma, i-crosshead, njll., eguqula ukunyakaza okujikelezayo kwendlela yokushayela ibe ukunyakaza okuphindaphindayo komugqa wepiston. Ukuzungezisa kwe-crankshaft kushayela induku yokuxhuma ukuthi inyakaze, ngaleyo ndlela iphushe i-crosshead ukwenza ukunyakaza okuphindaphindayo kusilayidi.

Isibonelo, idizayini yama-crankshaft ivamise ukusebenzisa izinto zensimbi yealloy enamandla amakhulu enziwa ukunemba kwemishini nokwelashwa kokushisa ukuze kuqinisekiswe ukuthi inamandla anele nokuqina. Induku yokuxhuma yenziwe ngezinto ezinhle kakhulu zensimbi ezakhiwe, futhi ngokucubungula okunembile nokuhlanganisa, iqinisekisa ukuxhumana okuthembekile ne-crankshaft kanye ne-crosshead.

1.3 Umzimba wePiston nesilinda

I-piston iyisakhi esithintana ngqo negesi ku-compressor ye-diaphragm, eyenza ukunyakaza okuphindaphindiwe ngaphakathi kwesilinda ukuze kuzuzwe ukucindezelwa kwegesi. Umzimba we-cylinder uvame ukwenziwa ngensimbi enamandla kakhulu noma insimbi eyinsimbi, enokumelana okuhle nokucindezela. Izivalo zisetshenziswa phakathi kwepiston nesilinda ukuvimbela ukuvuza kwegesi.

Isibonelo, ingaphezulu le-piston livame ukuphathwa ngokwelashwa okukhethekile okufana ne-chrome plating, i-nickel plating, njll. Ukukhethwa kwezingxenye zokuvala nakho kubalulekile, ngokuvamile kusetshenziswa irabha esebenza kahle kakhulu noma izigxivizo zensimbi ukuze kuqinisekiswe umphumela omuhle wokuvala.

1.4 Izingxenye ze-diaphragm

Ingxenye ye-diaphragm iyingxenye eyinhloko ye-compressor ye-diaphragm, ehlukanisa igesi ecindezelwe kumafutha okugcoba kanye nendlela yokushayela, iqinisekisa ukuhlanzeka kwegesi elicindezelwe. Izingxenye ze-diaphragm zivame ukwakhiwa ngamashidi e-diaphragm, amathreyi e-diaphragm, amapuleti okucindezela kwe-diaphragm, njll. Amashidi e-diaphragm ngokuvamile enziwe ngezinto eziqinile zensimbi noma zenjoloba, ezinokunwebeka okuhle kanye nokumelana nokugqwala.

Isibonelo, amapuleti ensimbi e-diaphragm ngokuvamile enziwe ngezinto ezifana nensimbi engagqwali ne-titanium alloy, futhi acutshungulwa ngamasu akhethekile ukuze abe namandla aphezulu kanye nokumelana nokugqwala. I-diaphragm yerabha yenziwe ngezinto ezikhethekile zenjoloba zokwenziwa, ezinokunwebeka okuhle kanye nezakhiwo zokuvala. Ithreyi le-diaphragm kanye nepuleti lomfutho we-diaphragm kusetshenziselwa ukulungisa i-diaphragm, ukuqinisekisa ukuthi i-diaphragm ngeke iguge noma iphuke ngesikhathi sokusebenza.

1.5 Ivalvu yegesi nohlelo lokupholisa

I-valve yegesi iyingxenye ye-compressor ye-diaphragm elawula ukungena nokuphuma kwegesi, futhi ukusebenza kwayo kuthinta ngokuqondile ukusebenza kahle nokuthembeka kwe-compressor. I-valve yomoya ngokuvamile ithatha i-valve ezenzakalelayo noma i-valve ephoqelelwe, futhi ikhethwa ngokuvumelana nengcindezi yokusebenza kanye nezidingo zokugeleza ze-compressor. Uhlelo lokupholisa lusetshenziselwa ukunciphisa ukushisa okukhiqizwa i-compressor ngesikhathi sokusebenza, ukuqinisekisa ukusebenza okuvamile kwe-compressor.

Isibonelo, ama-valve azenzakalelayo ngokuvamile asebenzisa intwasahlobo noma i-diaphragm njenge-valve core, evula ngokuzenzakalelayo futhi ivale ngokushintsha kwengcindezi yegesi. Ivalvu ephoqelelwe idinga ukulawulwa ngezinqubo zokushayela zangaphandle, ezifana nedrayivu kagesi, i-pneumatic drive, njll. Isistimu yokupholisa ingase ipholiswe ngomoya noma ipholiswe ngamanzi, kuye ngendawo yokusebenza nezimfuneko ze-compressor.

2. Isimiso sokusebenza se-diaphragm compressor

Inqubo yokusebenza ye-compressor ye-diaphragm ingahlukaniswa izigaba ezintathu: ukuncela, ukucindezelwa, nokukhipha:

2.1 Isiteji sokuhogela

Lapho i-piston ihamba ngakwesokudla, ingcindezi ngaphakathi kwesilinda iyancipha, i-valve yokungena iyavuleka, futhi igesi yangaphandle ingena emzimbeni we-cylinder ngepayipi lokungena. Ngalesi sikhathi, ipuleti le-diaphragm ligoba ngakwesobunxele ngaphansi kwesenzo sokucindezela ngaphakathi kwe-cylinder kanye nokucindezela ekamelweni le-diaphragm, futhi umthamo wekamelo le-diaphragm uyanda, wenza inqubo yokudonsa.

Isibonelo, ngesikhathi senqubo yokuphefumula, ukuvulwa nokuvalwa kwe-valve yokungena kulawulwa umehluko wengcindezi ngaphakathi nangaphandle kwe-cylinder block. Lapho ingcindezi ngaphakathi kwe-cylinder iphansi kunokucindezela kwangaphandle, i-valve yokungenisa ivula ngokuzenzakalelayo futhi igesi yangaphandle ingena emzimbeni we-cylinder; Lapho ingcindezi ngaphakathi kwe-cylinder ilingana nokucindezela kwangaphandle, i-valve yokudonsa ivala ngokuzenzakalelayo futhi inqubo yokudonsa iyaphela.

2.2 Isigaba sokucindezela

Lapho i-piston ihamba kwesokunxele, ingcindezi ngaphakathi kwesilinda kancane kancane ikhula, i-valve yokudonsa iyavaleka, futhi i-valve yokukhipha igesi ihlala ivaliwe. Kuleli qophelo, ipuleti le-diaphragm ligobela kwesokudla ngaphansi kwengcindezi ngaphakathi kwesilinda, lehlisa ivolumu yegumbi le-diaphragm futhi licindezela igesi. Njengoba i-piston iqhubeka nokunyakaza, ingcindezi ngaphakathi kwesilinda ikhuphuka ngokuqhubekayo ize ifinyelele ukucindezela okumisiwe okumisiwe.

Isibonelo, ngesikhathi sokucindezela, ukuguqulwa kokugoba kwe-diaphragm kunqunywa umehluko phakathi kwengcindezi ngaphakathi kwe-cylinder kanye nokucindezela ekamelweni le-diaphragm. Lapho ukucindezela ngaphakathi kwesilinda kungaphezu kokucindezela ekamelweni le-diaphragm, ipuleti le-diaphragm ligoba kwesokudla, licindezela igesi; Lapho ingcindezi ngaphakathi kwesilinda ilingana nokucindezela egumbini le-diaphragm, i-diaphragm ilingana futhi inqubo yokucindezela iyaphela.

3.3 Isiteji sokuqeda amandla

Lapho ingcindezi ngaphakathi kwe-cylinder ifinyelela ukucindezela kokucindezela okuhleliwe, i-valve yokukhipha iyavula futhi igesi ecindezelwe ikhishwa ku-cylinder ngokusebenzisa ipayipi yokukhipha. Kuleli qophelo, ipuleti le-diaphragm ligoba ngakwesobunxele ngaphansi kwengcindezi ngaphakathi kwesilinda kanye negumbi le-diaphragm, likhulisa umthamo wegumbi le-diaphragm futhi lilungiselela inqubo yokumunca elandelayo.

Isibonelo, phakathi nenqubo yokukhipha, ukuvulwa nokuvalwa kwe-valve yokukhipha kulawulwa umehluko phakathi kokucindezela ngaphakathi kwe-cylinder kanye nokucindezela kwipayipi yokukhipha. Lapho ingcindezi ngaphakathi kwe-cylinder iphakeme kunokucindezela kwipayipi yokukhipha, i-valve yokukhipha ivula ngokuzenzakalelayo futhi igesi ecindezelwe ikhishwa emzimbeni we-cylinder; Lapho ingcindezi ngaphakathi kwe-cylinder ilingana nokucindezela kwipayipi yokukhipha, i-valve yokukhipha ivala ngokuzenzakalelayo futhi inqubo yokukhipha iphelile.

3. Izimpawu kanye nokusetshenziswa kwe-Diaphragm Compressors

3.1 Izici

Ukuhlanzeka okuphezulu kwegesi ecindezelwe: Ngenxa ye-diaphragm ehlukanisa igesi ecindezelwe kumafutha okugcoba kanye nendlela yokushayela, igesi ecindezelwe ayingcoliswa uwoyela wokugcoba nokungcola, okuholela ekuhlanzekeni okuphezulu.

Ukubekwa uphawu okuhle: I-compressor ye-diaphragm yamukela isakhiwo sokuvala esikhethekile, esingavimbela ngokuphumelelayo ukuvuza kwegesi, ukuqinisekisa ukusebenza kahle kokucindezela nokuphepha.

Ukusebenza okushelelayo: Ngesikhathi senqubo yokusebenza ye-compressor ye-diaphragm, isivinini sokunyakaza kwe-piston siphansi, futhi akukho ukuxhumana okuqondile phakathi kwezingxenye zensimbi, ngakho-ke ukusebenza kushelela futhi umsindo uphansi.

Ukuzivumelanisa nezimo okuqinile: Ama-compressor e-diaphragm angakwazi ukuzivumelanisa nezidingo ezihlukahlukene zokucindezelwa kwegesi, okuhlanganisa ukucindezela okuphezulu, ukuhlanzeka okuphezulu, amagesi akhethekile avuthayo kanye neziqhumane.

3.2 Isicelo

Imboni ye-Petrochemical: esetshenziselwa ukucindezela amagesi afana ne-hydrogen, i-nitrogen, igesi yemvelo, njll., ehlinzeka ngezinto ezingavuthiwe namandla okukhiqiza amakhemikhali.

Imboni yokudla neyokwenza imithi: isetshenziselwa ukucindezela amagesi afana nomoya ne-nitrogen, ihlinzeka ngendawo yegesi ehlanzekile yokucubungula ukudla kanye nokukhiqizwa kwemithi.

Imboni ye-elekthronikhi semiconductor: esetshenziselwa ukucindezela amagesi ahlanzekile njenge-nitrogen, i-hydrogen, i-helium, njll., ehlinzeka ngendawo yegesi ehlanzekile kakhulu yokukhiqiza ama-chip kagesi kanye nokukhiqizwa kwe-semiconductor.

Emkhakheni wokuhlolwa kocwaningo lwesayensi, isetshenziselwa ukucindezela amagesi akhethekile ahlukahlukene futhi inikeze ukuhlinzekwa kwegesi okuzinzile kokuhlolwa kocwaningo lwesayensi.

Kafushane, ama-compressor e-diaphragm adlala indima ebalulekile emikhakheni eminingi ngenxa yesakhiwo sawo esiyingqayizivele kanye nesimiso sokusebenza. Ukuqonda isimiso sokusebenza se-diaphragm compressors kungasiza ekusebenziseni kangcono nokugcina lesi sisetshenziswa, sithuthukise ukusebenza kahle nokuthembeka kwayo.

Isikhathi sokuthumela: Sep-12-2024