Abstract: Enye yezingxenye ze-compressor ye-diaphragm i-diaphragm yensimbi, ethinta ukuthi i-compressor ingasebenza isikhathi eside, futhi ihlobene nempilo yesevisi yomshini we-diaphragm. Lesi sihloko sihlola izici eziyinhloko zokuhluleka kwe-diaphragm kuma-diaphragm compressors kanye nendlela yokwelula impilo yesevisi ye-diaphragm yensimbi ye-diaphragm compressor ngokuhlola izimo zokusebenza ze-compressor ye-test loop device recovery compressor, impahla ye-diaphragm yensimbi kanye nesistimu kawoyela we-compressor we-hydraulic.

Amagama angukhiye: I-compressor ye-diaphragm; i-diaphragm yensimbi; ukuhlaziya imbangela; izinyathelo zokuphikisa

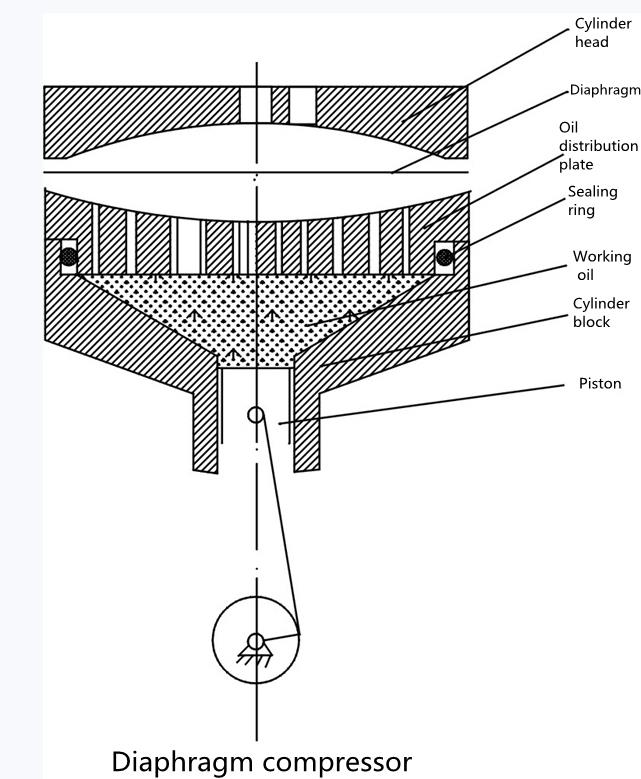

I-diaphragm ye-compressor ye-diaphragm ngokuyinhloko isetshenziselwa ukusebenza kwegesi, ukuze kuzuzwe inhloso yokudlulisa igesi nokucindezelwa.

I-diaphragm iyisakhi esisetshenziswa kakhulu ekusebenzeni kwe-compressor. Izidingo ze-diaphragmimpahlaziqinile kakhulu.Kumele ibe nokunwebeka okuhle nokumelana nokukhathala, ukuze impilo yesevisi inwetshwe. Ukuphuka kwe-diaphragm kwenzeka, ikakhulukazi ngenxa yokukhetha okungalungile kwe-diaphragm kanye nobuchwepheshe bokusebenza obungalungile ngesikhathi sokusebenza.

I-compressor ye-diaphragm yesitshalo samakhemikhali inezidingo eziqinile zokuphepha. Ngaphezu kokuhlangabezana nemisebenzi edingwa impilo yansuku zonke, umsipha okhethiwe we-diaphragm kufanele futhi ucatshangelwe ngokugcwele mayelana nokuphepha. Indima yemojula yensimbi ye-cadmium ukuhlukanisa igesi yenqubo kuwoyela we-hydraulic namafutha okugcoba, kanye nokuqinisekisa ukuhlanzeka kwegesi elicindezelwe.

1.Ukuhlaziywa kokwehluleka kwe-Compressor diaphragm

I-compressor ye-diaphragm yensimbi iyi-compressor ye-diaphragm ephindaphindayo. Ngesikhathi sokusebenza okujwayelekile kwe-compressor, uketshezi oluku-cylinder luzoqhutshwa yi-diaphragm. Kunezinhlobo ezintathu zokwehluleka kwe-diaphragm ngaphakathi kwe-compressor ye-diaphragm.

①Uma ingcindezi yekhanda le-membrane iphezulu kakhulu, izofinyelela esimweni sokuvala ukuvala kwenani eliphezulu lokungena; uma kwenzeka ukwehluleka, ukucindezelwa ekuphumeni kwe-compressor kuzofinyelela ukucindezela ukuthi inani eliphakeme le-interlock lingakwazi ukumelana, futhi ukuvala kuzoyeka.

②Ingcindezi ekuphumeni kwe-compressor iphansi kunevelu yokucindezela ebekiwe, futhi ukusabela kuyanqanyulwa ngoba umqalisi akajovwe ngokwanele. Lapho ukucindezela kwe-compressor kuncipha, ngesikhathi esifanayo, indawo ye-valve ye-valve elawula ingcindezi endaweni yokuphuma izokhula kancane kancane. Isikhundla se-valve sizolahlekelwa ukusebenza kwayo kokulawula nokufinyelela100%. Lapho ingcindezi yokuphuma iphansi kunengcindezi eshiwo ye-MPa, ukusabela kwayo kuzothinteka, futhi nokuqedwa kuzokwenzeka.

③Lapho i-diaphragm isebenza ngochungechunge, izocupha ukuvala shaqa kweketango. Njengoba i-compressor ifakiwe futhi isetshenziswa, ibisebenza ngokujwayelekile. Njengoba i-compressor yokutakula ekhethiwe iyisethi yamadivayisi okuhlola, kunezifunda eziningi zokuqalisa nokuvala i-compressor, futhi izimo zokusebenza ze-diaphragm nazo ziba nzima nakakhulu lapho ukuhlolwa kwenziwa. Ekusebenzeni kwesikhathi eside, kungatholakala ukuthi impilo yesevisi ye-diaphragm yensimbi ingaphansi kwesigamu sempilo yesevisi ngaphansi kokusebenza okujwayelekile. Ikakhulukazi, impilo yesevisi ye-diaphragm yokucindezela kwesigaba sesibili ye-compressor imfushane kakhulu; i-diaphragm ohlangothini lwamafutha lwe-compressor lonakaliswa kakhulu ebusika. I-diaphragm ye-compressor ivame ukulimala, futhi ekugcineni ibangele ukuvala nokuhlolwa njalo ngesikhathi sokuhlolwa, okubangela ukuphazamiseka okuningi.

1. I-compressor diaphragm ibonakala, futhi umonakalo wangaphambi kwesikhathi unezici ezilandelayo.

1.1 Izinga lokushisa likawoyela we-Compressor liphansi kakhulu

Uma izinga lokushisa liphansi kunendawo yokuqandisa ebusika, i-viscosity yamafutha we-hydraulic iphakeme kunesikhathi sokusebenza okuvamile. I-pilot loop tube device yale compressor iyithuluzi leshubhu lokuhlola, futhi le divayisi isetshenziswa kaningi phakathi nokuqaliswa nokuvala shaqa, futhi ukuqalisa kwe-compressor nokuvama kokuvala shaqa nakho kuphezulu uma kuqhathaniswa. Le compressor ayinalo uhlelo lokushisisa izinga lokushisa likawoyela. Lapho umshini wokunyathelisa we-hydraulic uqala, izinga lokushisa lokucindezela kwamafutha liphansi kakhulu futhi i-viscosity iphakeme kakhulu ngenxa yezizathu zezulu, okubangela ukuthi ukucindezela kwamafutha kawoyela we-hydraulic kube phansi kakhulu futhi uhlelo lwamafutha we-hydraulic alulungile. Yasungulwa. Ngesikhathi sokusebenza, igesi ecindezelwe ku-compressor izokwenza ukuthi i-diaphragm isondele ku-orifice plate kuyo yonke isixhumanisi sokusebenza, futhi ukucindezela kwegesi kuzobangela ukuthi i-diaphragm ihlale inomthelela, okuholela ekuguqulweni kwengxenye yembobo yomhlahlandlela kawoyela, i-diaphragm izoqhuma ngaphambi kokuba ifinyelele impilo yesevisi ecacisiwe.

1.2 Isimo sokusebenza se-Compressor

Ngokombono wegesi oyingxenye yengcindezi, kulula ukucwilisa ngaphansi kwezinga lokushisa elimisiwe nokucindezela komsebenzi, okubangela ukuthi igesi yasekuqaleni ngaphakathi kwe-compressor igcwale, futhi i-diaphragm yensimbi izothinteka yisigaba soketshezi, okuzokwenza ukuthi i-diaphragm ibonakale ngaphambi kwesikhathi. Umonakalo.

1.3 I-Compressor diaphragm impahla

Izinto ezisetshenziselwa i-compressor diaphragm yizinto eziye zaphathwa ngokukhethekile futhi zinezakhiwo ezinhle zomshini. Ububi balokhu ukuthi ukumelana nokugqwala kuzoba buthakathaka. Kodwa-ke, lapho kukhiqizwa ithubhu leringi lomshayeli Kuzoba khona inani elincane lendawo ebolayo engakaze ibhekane nokusabela kwamakhemikhali, futhi ingena ohlelweni lokubuyisela ngaphandle kokwelashwa okukhethekile. I-compressor diaphragm ibhekene nale nkinga. Ngaleso sikhathi, lapho ukhetha impahla ye-diaphragm, ubukhulu bebukhona kuphela0.3mm, ngakho amandla ayeyoba buthakathaka uma kuqhathaniswa.

2. Izinyathelo zokunweba impilo yesevisi ye-compressor diaphragm

Impilo yesevisi ye-diaphragm ye-compressor ye-diaphragm ibaluleke kakhulu. Lapho ukusebenza kwe-compressor kuhlangabezana nezinga, ukwethembeka kwe-compressor kwahlulelwa impilo yesevisi ye-diaphragm yensimbi. Izici ezingathinta impilo ye-diaphragm zihlanganisa izici ezilandelayo, njengemvelo yegesi ecindezelweyo, ukuzinza kwamafutha we-hydraulic, kanye nempahla ye-diaphragm. Isizathu sokuphuka ngaphambi kwesikhathi komshini wokucindezelwa kwe-diaphragm sahlaziywa futhi kwasungulwa uhlelo lokuthuthukisa.

2.1 Khulisa isistimu yokushisa kagesi kawoyela we-hydraulic

Ithangi likawoyela le-compressor lidinga ugesi ukuze likhiqize ukushisa, futhi kuyadingeka ukunquma ukuthi kufanele kusetshenziswe ukufudumeza kwamafutha ngokwezinga lokushisa elizungezile. Ebusika, lapho izinga lokushisa lifinyelela izinga lokubanda futhi linjalongaphansi kuka 18 degreesI-Celsius, uwoyela we-hydraulic kufanele ushiswe ngokuzenzakalelayo ngogesi. Lapho izinga lokushisa likhonangaphezu kwama-degree angama-60, inkinobho yokushisa kagesi kufanele icishwe ngokuzenzakalelayo, futhi izinga lokushisa langaphandle kufanele ligcinwe lihambisana nokushisa ngaso sonke isikhathi. Okujwayelekile ukuvimbela umonakalo womthelela we-diaphragm obangelwa umfutho ophansi kawoyela kanye nezinga lokushisa

2.2 Ukuthuthukisa izimo zenqubo

Ipayipi le-pilot loop kufanele lenziwe lilungiswe ngendlela efanele futhi lithuthukiswe ngokuvumelana nezimo zokusebenza ze-compressor. Ngokwesisekelo sokuqinisekisa ukusebenza okuzinzile kwesistimu elandelayo, izinga lokushisa lokuphuma kwe-compressor kufanele lenyuke, futhi ukucindezela kokuphuma kwe-compressor kufanele kuncishiswe ngokufanele. Vimbela umthelela wesigaba soketshezi obangelwa ukuphuphuma kwe-n-hexane, futhi wandise impilo yesevisi ye-diaphragm yensimbi.

2.3 Ukulungisa kabusha i-diaphragm yensimbi

Ukuze ukhethe kabusha i-diaphragm yensimbi, kuyadingeka ukukhetha into enokuqina okuphezulu, amandla aphezulu, nokumelana nokugqwala okuhle. Ubuchwepheshe bokucubungula be-diaphragm yensimbi kufanele futhi buthuthukiswe.

①Ukuze kuthuthukiswe amandla, ukumelana nokugqwala kanye nokuzimisela kwempahla, impahla kufanele ilashwe ngokuguga.

②Ngemuva kokuthi umshini usuqediwe, ukuze unciphise ukucindezela ngaphakathi kwe-diaphragm yensimbi ngangokunokwenzeka, kuyadingeka ukupholisha izinhlangothi zombili ze-diaphragm.

③Ukwandisa impilo yesevisi ye-diaphragm, kuyadingeka ukusebenzisa izinto zokulwa nokugqwala ezinhlangothini zombili zengxenye ephakathi ye-diaphragm ukuvimbela i-diaphragm ukuthi ingakhuhlani komunye nomunye futhi ibangele ukugqwala.

④Ubukhulu be-diaphragm buyanda ukuze kwandiswe amandla e-diaphragm, futhi impilo yesevisi ye-diaphragm izokwelulwa.

Isiphetho Kule nqubo yokuhlola engenhla, i-diaphragm ye-compressor iye yathuthukiswa futhi nezimo zayo zokusebenza zenziwa zaba ngcono. Ekusebenzeni kwangempela kwe-compressor ye-diaphragm, impilo yesevisi ye-diaphragm yensimbi iyandiswa, okukhuthaza i-compressor ye-diaphragm ukuthi ikwazi ukuhlala isikhathi eside.

Isikhathi sokuthumela: Nov-30-2021