I-Industrial High Purity High Pressure Oxygen Helium Diaphragm Compressor

I-Xuzhou Huayan Gas Equipment Co., Ltd.ungumhlinzeki ophambili womhlaba wonke wezixazululo zokucindezelwa kwegesi. Ngobungcweti obuqoqiwe bokuklama nokukhiqiza amashumi eminyaka, inkampani yethu inamakhono aphelele okukhiqiza ahlanganisa ukukhanga okuchwepheshile, ukuphonsa, ukwelashwa kokushisa, ukushisela, ukunemba kwemishini, ukuhlolwa kwenhlangano, nezinqubo zokuqinisekisa ikhwalithi. Sisekelwa ithimba lezobuchwepheshe elizinikele lezingcweti eziyi-120 kanye nendawo yokukhiqiza engu-90,000 m², sigcina okokusebenza okuthuthukisiwe kokuhlola kanye nezindlela eziqinile zokulawula ikhwalithi ukuze siqinisekise ukusebenza kahle komkhiqizo.

Iyakwazi ukuklama ngokwezifiso, ukukhiqiza, kanye nokufaka imishini ngokuya ngemingcele ethile yamakhasimende, okwamanje sifinyelela umthamo wonyaka wokukhiqiza wamayunithi angama-500 wegesi compressor. Ubuhle bethu bezobuchwepheshe buvumela ukuthuthukiswa kwama-compressor anengcindezi yokukhipha ifike ku-100MPa, ehlangabezana nezidingo zezimboni ezidingeka kakhulu.

Ngophawu lomhlaba wonke oludlulela emazweni angaphezu kuka-50 kuwo wonke amazwekazi amahlanu, okuhlanganisa izimakethe ezibalulekile njenge-Indonesia, i-Egypt, iVietnam, iNingizimu Korea, iThailand, iFinland, i-Australia, i-Czech Republic, i-Ukraine, ne-Russia, siletha izixazululo eziphelele ze-turnkey kumakhasimende emhlabeni jikelele. Ukuzibophezela kwethu ekusebenzeni kahle kuqinisekisa ukuthi wonke amakhasimende athola izinto zokusebenza ezisebenza kahle ezibhangqwe nokusekelwa kobuchwepheshe obuchwepheshile kanye nesevisi ephendulayo.

SQUARE imitha

IQEMBU LEZOBUCHWEPHESHE

UKWENZIWA KOMUZI

Ithekelisa AMAZWE

A I-compressor ye-diaphragmiyi-compressor ekhethekile yokufuduka edume ngekhono layo lokuphatha amagesi ngobumsulwa obukhethekile, ukuzwela, noma ubungozi ngaphandle kokungcola noma ukuvuza. Ngokungafani nama-piston compressor endabuko, isebenzisa i-diaphragm eguquguqukayo, esebenza nge-hydraulically actuated ukuhlukanisa igesi ecindezelwe ku-crankcase egcotshiwe kanye nepiston.

Izici Eziyinhloko:

1,Ukubekwa uphawu kwe-Hermetic: I-metal noma i-elastomer diaphragm idala umgoqo ophelele, ongavuzi phakathi kwegesi kanye noketshezi olusebenza ngamanzi/ okokugcoba. Lesi yisici sayo esichazayo.

2,Zero Ukungcola: Iqinisekisa ukuthi igesi ecindezelwe ihlala ingenawo uwoyela ngokuphelele futhi ingangcolisiwe izinto zokugcoba noma izinhlayiya ezigugile ezisuka kumshini wokushayela. Ibalulekile ezinhlelweni zokusebenza zokuhlanzeka okuphezulu.

3,Ukuvimbela Ukuvuza: Icishe iqede ukukhishwa okuphumayo okubalekayo, ikwenze kube semqoka ukuphatha amagesi anobuthi, avuthayo, aqhumayo, noma alimaza imvelo.

4,Amandla Okucindezela Okuphezulu: Iyakwazi ukufeza izingcindezi eziphezulu kakhulu zokukhipha (ngokuvamile kufika ku-3000 bar / 43,500 psi nangaphezulu), ikakhulukazi ekucushweni kwezigaba eziningi.

5,Ukuphatha Igesi Okuhlukahlukene: Ifanele ukuminyanisa izinhlobonhlobo zamagesi, okufaka phakathi izinhlobo ezisebenza ngamandla, ezibolayo, ezihlanzekile kakhulu, ezibizayo, noma eziyingozi ezingalimaza noma zingcoliswe eminye imiklamo ye-compressor.

6,Amazinga Okugeleza Okumaphakathi: Ngokuvamile yakhelwe amazinga okugeleza aphansi kuya kwamaphakathi uma kuqhathaniswa nama-compressor amakhulu aphindaphindayo noma ama-centrifugal.

Amagesi Afanelekile

Amagesi Afanelekile

1, Impilo ende yesevisi

Impahla yekhanda le-cylinder ye-diaphragm compressor iyakhiwa futhi icutshungulwe, futhi ngemva kokwelashwa kokushisa, impahla inokumelana nokucindezela okuphezulu, okunweba impilo yesevisi yemishini okungenani iminyaka engu-20.

2. Ukumelana nokugqwala

Ipayipi le-compressor ye-diaphragm lenziwe nge-SS304 noma i-SS316L yensimbi engagqwali, ethuthukisa ukumelana nokugqwala kwemishini ezindaweni ezinomswakama ne-acidic, ngaphandle kokugqwala, futhi inokubukeka okuhle.

I-3, ingcindezi ephezulu yokukhipha amandla

Ingcindezi yokukhipha i-compressor ye-diaphragm ingafinyelela ku-90MPa.

4, Impilo ende yesevisi yezingxenye ezisengozini

Kuma-compressor apholile amanzi, kunezimbobo zeziteshi zamanzi ezi-5 ekhanda lesilinda. Ngaphezu kwesipholile samanzi sangaphandle esinciphisa izinga lokushisa legesi, sipholise ikhanda lesilinda ukuze sinciphise igesi futhi sandise impilo yesevisi ye-diaphragm ne-valve. Isilinganiso sempilo yesevisi ye-diaphragm singafinyelela ngaphezu kuka-5000h.

5. Ukusebenza kahle kokubekwa uphawu

Ikhanda lesilinda liklanywe ngokufakwa kabili kwe-O-ring, futhi umphumela wokuvala uphakeme kakhulu kunekhanda lolwelwesi oluvulekile.

1,I-Petrochemical & Chemical Processing: Ukucindezelwa kweziphakathi ezigqwala kakhulu, izinto ezisabelayo ezinobuthi (isb, ekukhiqizweni kwe-PVC nge-Cl₂), amagesi avuselela amandla, ukucindezela kwe-hydrogen kuma-hydrocrackers/ama-hydrotreaters lapho ubumsulwa bubaluleke kakhulu.

2,Amafutha Negesi: Ukucindezelwa kwegesi ye-Subsea, umjovo wegesi (ukubuyiswa kukawoyela okuthuthukisiwe), ukucindezelwa kwe-hydrogen ezindaweni zokuhluza.

3,Ukukhiqiza I-Semiconductor: Ibalulekile ekuhlinzekeni ukuhlanzeka okuphezulu kakhulu (UHP) namagesi akhethekile ayingozi (njenge-Ash₃, PH₃, SiH₄) kumathuluzi okukhiqiza ngaphandle kokungcola.

4,I-Analytical & Laboratory: Ihlinzeka ngamagesi enkampani yenethiwekhi amsulwa, angangcolisi, amagesi okulinganisa, namagesi ayisampula kumathuluzi afana ne-GC-MS.

5,I-Aerospace nokuhlola: Ukunikezwa kwegesi enomfutho ophezulu (Yena, N₂) wokuhlola izingxenye zerokhethi, izinhlelo ezicindezelayo, imigudu yomoya.

6,Ezokwelapha Nezemithi: Ukukhiqizwa nokufaka amabhodlela amagesi ezokwelapha ahlanzekile kakhulu (O₂, N₂O), umoya oyinyumba wezinqubo.

7,Imboni Yenuzi: Ukuphatha izinto zokupholisa i-helium noma amagesi okuvala.

8,Amandla neHydrojeni: Ukucindezelwa kwe-hydrogen kumaseli kaphethiloli, iziteshi ze-hydrogen refueling (HRS), kanye nocwaningo lokukhiqizwa/kwesitoreji se-hydrogen.

9,Ubuchwepheshe Bezemvelo: Icindezela i-CO₂ ethwebuliwe ukuze ithathwe noma isetshenziswe (CCUS).

| Imodeli | Ukusetshenziswa kwamanzi okupholisa (t/h) | Ukususwa (Nm³/h) | I-Intake pressure (MPa) | I-Exhaust pressure (MPa) | Ubukhulu L×W×H(mm) | Isisindo (t) | Amandla Emotor (kW) | |

| 1 | I-GL-10/160 | 1 | 10 | 16 | 2200×1200×1300 | 1.6 | 7.5 | |

| 2 | I-GL-25/15 | 1 | 25 | 1.5 | 2200×1200×1300 | 1.6 | 7.5 | |

| 3 | I-GL-20/12-160 | 1 | 20 | 1.2 | 16 | 2200×1200×1300 | 1.6 | 7.5 |

| 4 | I-GL-70/5-35 | 1.5 | 70 | 0.5 | 3.5 | 2000×1000×1200 | 1.6 | 15 |

| 5 | I-GL-20/10-150 | 1.5 | 20 | 1.0 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 6 | I-GL-25/5-150 | 1.5 | 25 | 0.5 | 15 | 2200×1200×1300 | 1.6 | 15 |

| 7 | I-GL-45/5-150 | 2 | 45 | 0.5 | 15 | 2600×1300×1300 | 1.9 | 18.5 |

| 8 | I-GL-30/10-150 | 1.5 | 30 | 1.0 | 15 | 2300×1300×1300 | 1.7 | 11 |

| 9 | I-GL-30/5-160 | 2 | 30 | 0.5 | 16 | 2800×1300×1200 | 2.0 | 18.5 |

| 10 | I-GL-80/0.05-4 | 4.5 | 80 | 0.005 | 0.4 | 3500×1600×2100 | 4.5 | 37 |

| 11 | I-GL-110/5-25 | 1.4 | 110 | 0.5 | 2.5 | 2800×1800×2000 | 3.6 | 22 |

| 12 | I-GL-150/0.3-5 | 1.1 | 150 | 0.03 | 0.5 | 3230×1770×2200 | 4.2 | 18.5 |

| 13 | I-GL-110/10-200 | 2.1 | 110 | 1 | 20 | 2900×2000×1700 | 4 | 30 |

| 14 | I-GL-170/2.5-18 | 1.6 | 170 | 0.25 | 1.8 | 2900×2000×1700 | 4 | 22 |

| 15 | I-GL-400/20-50 | 2.2 | 400 | 2.0 | 5.0 | 4000×2500×2200 | 4.5 | 30 |

| 16 | I-GL-40/100 | 3.0 | 40 | 0.0 | 10 | 3700×1750×2000 | 3.8 | 30 |

| 17 | I-GL-900/300-500 | 3.0 | 900 | 30 | 50 | 3500×2350×2300 | 3.5 | 55 |

| 18 | I-GL-100/3-200 | 3.5 | 100 | 0.3 | 20 | 3700×1750×2150 | 5.2 | 55 |

| 19 | I-GL-48/140 | 3.0 | 48 | 0.0 | 14 | 3800×1750×2100 | 5.7 | 37 |

| 20 | I-GL-200/6-60 | 3.0 | 200 | 0.6 | 6.0 | 3800×1750×2100 | 5.0 | 45 |

| 21 | I-GL-140/6-200 | 5.0 | 140 | 0.6 | 20.0 | 3500×1380×2350 | 4.5 | 55 |

| 22 | I-GL-900/10-15 | 2.5 | 900 | 1.0 | 1.5 | 3670×2100×2300 | 6.5 | 37 |

| 23 | I-GL-770/6-20 | 4.5 | 770 | 0.6 | 2.0 | 4200×2100×2400 | 7.6 | 55 |

| 24 | I-GL-90/4-220 | 6.0 | 90 | 0.4 | 22.0 | 3500×2100×2400 | 7.0 | 45 |

| 25 | I-GL-1900/21-30 | 3.8 | 1800 | 2.1 | 3.0 | 3700×2000×2400 | 7.0 | 55 |

| 26 | I-GL-300/20-200 | 4.2 | 300 | 2.0 | 20.0 | 3670×2100×2300 | 6.5 | 45 |

| 27 | I-GL-200/15-200 | 4.0 | 200 | 1.5 | 20.0 | 3500×2100×2300 | 6.0 | 45 |

| 28 | I-GL-330/8-30 | 5.0 | 330 | 0.8 | 3.0 | 3570×1600×2200 | 4.0 | 45 |

| 29 | I-GL-150/6-200 | 5.0 | 150 | 0.6 | 20.0 | 3500×1600×2100 | 3.8 | 55 |

| 30 | I-GL-300/6-25 | 4.5 | 300 | 0.6 | 2.5 | 3450×1600×2100 | 4.0 | 45 |

Siphethe izitifiketi eziqashelwa umhlaba wonke kubandakanyaCEfuthiISOamazinga (agunyazwe nguIAF), kanye neI-ECMukuqashelwa kokuthobela. Lezi zitifiketi zibonisa ukuzibophezela kwethu okungantengantengi kukhwalithi, ukuphepha, kanye nesibopho semvelo:

- CE Ukumakaiqinisekisa ukuthobela imithetho ye-EU yokuphepha, yezempilo, neyemvelo, iqinisekisa ukufinyelela ezimakethe zamahhala kulo lonke elaseYurophu.

- Isitifiketi se-ISO(okusekelwa ukugunyazwa kwe-IAF) kuqinisekisa ukunamathela kwethu ezinhlelweni zokuphatha ikhwalithi ezilinganiselwe emhlabeni wonke, okuthuthukisa ukungaguquguquki kokusebenza kanye nokuzethemba kwamakhasimende.

- Ukuqashelwa kwe-ECMigcizelela ukuvumelanisa kwethu namazinga obuchwepheshe aqondene nemboni kanye nokusebenza.

Uma imakethe yakho noma iphrojekthi yakho idinga izitifiketi ezengeziwe (isb,I-API,ASME, noma ukugunyazwa okuqondene nesifunda), ithimba lethu elinolwazi lwezobuchwepheshe kanye nokuthobela lizosebenzisana nawe ukuze lithole izitifiketi ezidingekayo. Silungisa izinqubo zethu ukuze zihlangabezane nezidingo zakho zokulawula, siqinisekise ukungena emakethe okungenamphetho kwamathuluzi ethu.

Eyethu90,000+Square mithaindawo yokukhiqiza yesimanje, inabasebenzi120+ochwepheshe, iletha izixazululo zobunjiniyela ezingokwezifiso ezinamakhono okukhiqiza anembayo. Ifakwe 20 eziphambili CNC machining izikhungo, siphatha workpieces kuze kube1200mmububanzi ngokunemba kwezinga le-micron (0.01mm). Izimiso eziqinile zokulawula ikhwalithi zihlanganisa ukuhlolwa okugcwele kwezingxenye ezibalulekile kusetshenziswa i-CMM (Imishini Yokukala Edidiyelwe) kanye nokuhlolwa komthwalo wezigaba eziningi onjiniyela abaqinisekisiwe ngemva kokuhlanganiswa. Yonke iyunithi ithola ukuqinisekiswa kokusebenza ukuze ihambisane namazinga e-ASME/API kanye nokucaciswa kweklayenti, okusekelweI-ISO 9001-eqinisekisiweukuphathwa kwekhwalithi ukuze kulandeleke, ukulethwa okuthembekile.

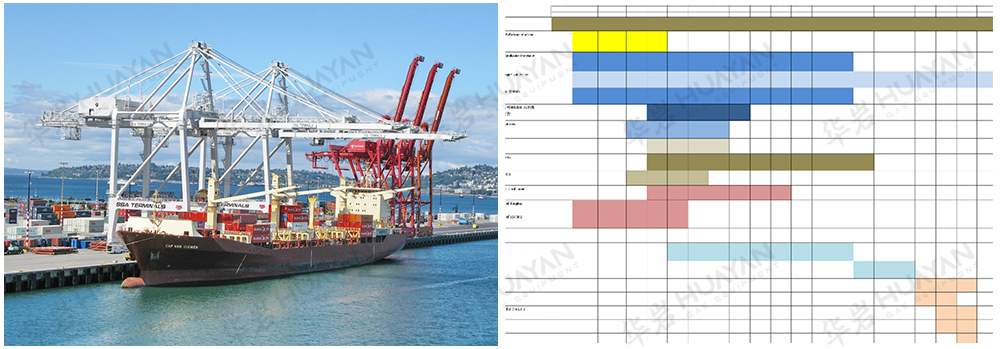

Sisebenzisai-fumigation-freeizinhlaka eziqinile zokhunikugunyazwe ukuthekelisa kwamanye amazwe kwe-ISOizindinganiso zokuhlukaniswa. Iqiniswe ngaphakathi ngensimbi yesiteshi ukuze isekele izinhlangothi ezintathu, ingaphandle isongwe ngonogada bekhona obujiyile abangu-0.8mm futhi ivikelwe emajoyintini kusetshenziswa.izintambo zensimbi ezingenamanzi. Lo mklamo uqinisekisa ukumelana nomthelela, ukuqina kokumelana nokucindezelwa, ukuvikela umswakama, nokuvikela ukugqwala kukho konke ukuhamba, okuqinisekisa ukuthi izimpahla zakho zifika ngokuphephile.

Inkampani yethu izothuthukisa amashejuli okulethwa enziwe ngokwezifiso ephrojekthi yakho, asekelwa izixazululo ezididiyelwe zokuphathwa kwempahlaezokuthutha emoyeni, olwandle nasemhlabeni.

Ngokusebenzisa inethiwekhi yasekhaya yaseShayina kanye nobambiswano lomhlaba wonke, siqinisekisa ukusebenza okuphumelelayo kwemingcele ngokulandela umkhondo ngesikhathi sangempela, ukwesekwa kokuvunyelwa kwezimpahla ezithengiswayo, namandla okugcina impahla. Ukuguquguquka kwe-Multi-modal kuqinisekisa ukulethwa kwezindleko kanye nokufika ngesikhathi kwazo zonke izinhlobo zempahla.

1.Ungayithola kanjani i-quotation esheshayo ye-gas compressor?

1)Izinga Lokugeleza/Umthamo : ___ Nm3/h

2)I-Suction/Inlet Pressure: ____ Ibha

3)I-Discharge/Outlet Pressure :____ Ibha

4)I-Gas Medium :_____

5)I-Voltage kanye Nemvamisa : ____ V/PH/HZ

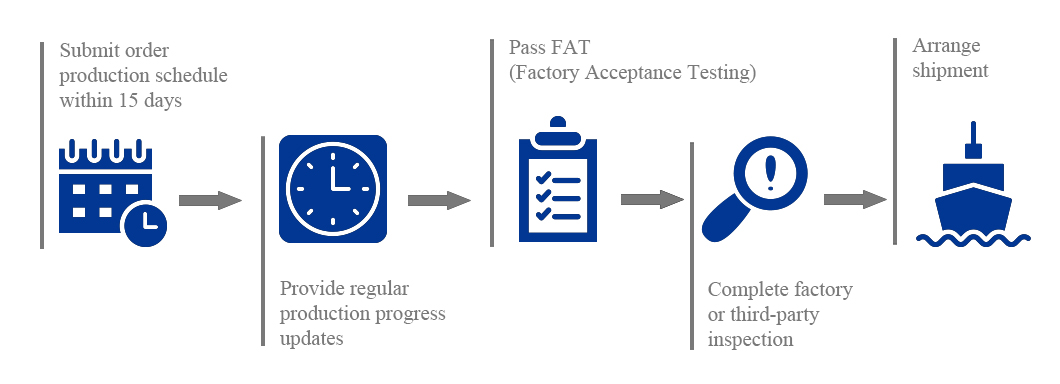

2.Singakanani isikhathi sokulethwa?

Isikhathi sokulethwa siyizinsuku ezingama-30-90.

3.Kuthiwani nge-voltage yemikhiqizo? Ingabe zingenziwa ngokwezifiso?

Yebo, i-voltage ingenziwa ngokwezifiso ngokuya ngokubuza kwakho.

4.Ungawamukela ama-oda we-OEM?

Yebo, ama-oda e-OEM amukelekile kakhulu.

5.Ingabe uzohlinzeka ngezingxenye ezisele zemishini?

Yebo

Ukufakwa kanye nokugunyazwa

Thumela izisebenzi zesevisi endaweni ukuze uqinisekise ukufakwa nokusebenza kahle kwemishini enikeziwe.

Sebenzisa ukuqeqeshwa

Ukufakwa kwamahhala nokuqondiswa kwemisebenzi, izinsiza zamahhala zobuchwepheshe, nokuqeqeshwa kwamahhala kwabasebenzi.

Ukuvakasha kokulandelela njalo

Yenza ukuvakasha kokulandelela njalo kusayithi futhi unikeze ngokushesha amasevisi okulandelela umkhiqizo.

Isevisi yezobuchwepheshe

Nikeza ngezinsizakalo zobuchwepheshe zamahhala ezidingekayo kuphrojekthi yokuvuselela.

7 Abantu

Ithimba lesevisi yangemuva kokuthengisa.

Izinga lokuphasa elingu-100%.

Thola izinga lokuphasa elingu-100% kusukela ekukhiqizeni nasekusetshenzisweni kuya ekuphathweni kwabahlinzeki.